It’s hard to radically improve the internal-combustion engine. But Shannon Miller may have done it, by getting it to work at extremely high compression and expansion ratios. Miller’s engines use 33 percent less fuel than conventional gas-powered generators.

While she was an engineer at Tesla motors the 33-year-old realised that operating engines at high compression and expansion ratios could make them far more efficient, but that’s easier said than done. High compression ratios create extreme temperatures, wasting energy. And high pressure increases friction between the piston and the cylinder.

So she turned to a “free-piston” design, an old idea that allows each piston to bounce up and down independently of any rod or crankshaft. The approach had not been used to operate pistons at very high compression ratios. “To make this work, you can’t just change one or two things,” she says. “You really need to change the whole architecture of the engine.”

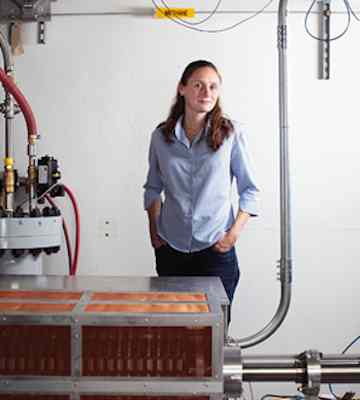

After a year at Tesla, Miller cofounded EtaGen, which aims to bring the engine to market. The company has built a prototype that runs for hours at target performance levels. She says upcoming versions of the engine should be about as efficient as large power plants — the current gold standard for energy efficiency — once the energy the plants lose during distribution is factored in.

EtaGen’s first product will be a replacement for conventional diesel and natural-gas generators, allowing businesses to operate a building off the grid or to ride through power outages. The engines would run on diesel or natural gas, but far more efficiently than existing generators

2 Responses

This is not a rotary engine at all…the motion is all linear, Picture an old steam engine driving a flywheel.

https://onemech.blogspot.com/2012/04/free-piston-engine-in-gas-turbine-power.html

So is this the old Wankel engine making a come back ?