The Gratzel solar cell imitates Nature’s way of converting sunlight to energy and is slowly making its debut in a variety of products.

The technology uses a photosensitive dye to start its energy production, the same way leaves use chlorophyll to begin photosynthesis.

The dye-sensitized cells provide power for devices ranging from e-book readers to cellphones — and will take some interesting forms. For e-book readers, for example, the cells may be found in thin, flexible panels stitched into the reader’s cover.

German photonics expert Prof Michael Gratzel is the inventor of the dye-sensitised solar cells. often known as Gratzel cells or Gratzel solar cells. Because these are low-cost photovoltaics, they are largely being developed for use in Africa and India by G24 Innovations of California.

This means off-grid users in the West risk losing out on the earliest deployments although panels will also be housed in new lines of backpacks and sports bags, where they can recharge devices like cellphones and music players.

The technology, long in development, will work best in full, direct sunshine, said Gratzel, a chemist and professor at the Ecole Polytechnique Federale de Lausanne in Switzerland. But the cells will also make good use of dappled and ambient light, including the indoor light of fluorescent bulbs, he said.

According to Gratzel, such technology will soon be helping people in Africa to connect to the internet.

‘I was in Tanzania last year, and everyone has a mobile phone; but there’s no grid to charge them,’ he said.

In Africa, mobiles are the primary way to connect to the internet for information such as where to obtain the best price for crops. ‘G24 Innovations is proposing to make lightweight chargers and give them away for free, in a business model where it would recoup the cost through call charges,’ explained Gratzel. ‘We need incentives such as this.’

He also said that the cells could be used to power fridges, to preserve food and pharmaceuticals and to drive ozone-generating water purifiers.

Most photovoltaic cells are based on silicon or related inorganic materials, not dyes. Dr. Gratzel and an American colleague, Brian O’Regan, first reported on the new type of cell in the journal Nature in 1991, and Dr. Gratzel said that he and other colleagues had been working since then to refine the technology. Now G24 Innovations, a company in Campbell, Calif., that has licensed the technology, is using it to make solar panels at its plant in Cardiff, Wales, said John Hartnett, G24’s chief executive.

Some of the panels will be placed on covers designed as an accessory for Sony e-book readers, costing about $99. The cover supplies the power via a plug in a cradle along its spine.

The panels will also be installed on tennis bags, backpacks and messenger bags that have battery chargers within, as well as on bicycle, golf, shopping and beach bags. Prices of the bags will typically range from $149 to $249, depending on the materials and size of the bag.

Some bags are already available, including messenger bags from Tonino Lamborghini.

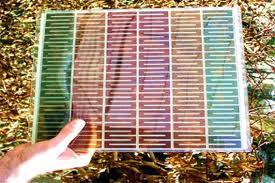

The solar panels have 11 cells each, said Kevin Tabor, director of science and research at G24. Wiring goes from the panel to a battery pack in the bag, he said. It takes about six to eight sunny hours outside for the panel to fuel the recharger, he said, but longer indoors.

The performance of the dye-sensitized cells has improved steadily in the laboratory, Dr. Gratzel said. ”Our dyes and electrolytes have changed,” he said, and the cells have become more efficient at converting sunlight to electricity.

In a conventional silicon-based photovoltaic cell, sunlight strikes the crystalline silicon surface and displaces an electron, which can then diffuse through the structure of the semiconductor, creating a current. The silicon is ‘doped’ with elements to increase its conductivity, easing the path of the electron. However, the efficiency is limited, and this is partly because the silicon meets the role of both energy harvesting and electron transport.

This isn’t the case in photosynthesis. Chlorophyll, the pigment that makes leaves green, acts as the energy harvester; it absorbs the light and generates a free electron. Other mechanisms within the plant’s cells then handle the movement of the electron, carrying it into the processes where it reacts with carbon dioxide and water to make glucose and oxygen.

In the early 1970s, concerns about the price of oil triggered a wave of research into alternative energy sources, and Gratzel became interested in photosynthesis. ‘At the time I was educated, the detail on how photosynthesis worked was not well established,’ he said. ‘I was interested by the way that plants use their molecules to generate charges and separate those charges.’

Gratzel cells copy this process, using three essential ingredients: a conductive electrolyte solution, in which is dispersed nanocrystals of the white pigment titanium dioxide (TiO2) coated with an organic dye. The dye takes the place of the chlorophyll – in early versions, chlorophyll itself was used, but electrons couldn’t diffuse through it – and absorbs sunlight, which knocks electrons free from the organic molecular structure of the highly coloured material. These are knocked into the TiO2, which has semiconducting properties, and carries the charge through the electrolyte to an external circuit. Electrons flowing back into the cell through the other side of the circuit replace those that are displaced from the dye molecules.

Gratzel’s first cells were perfected in the 1980s, as a result of work with new nanoscale forms of TiO2 created at Lausanne. ‘This was a fundamental study, driven by our curiosity – no one had done it before,’ he said. The research came to fruition in 1988, using a porous film coated with TiO2 crystals, creating a very high surface roughness to absorb sunlight.

‘I asked my PhD student Hans Desilvestro how the experiment had gone,’ Gratzel remembered. ‘He did not seem too enthusiastic initially, adding that he had only measured a few milliamperes current. I knew it was a lot; other researchers had only measured micro- or nano-amps.’

The initial cells achieved efficiencies of around seven per cent – a thousand times better than original versions from the 1970s – and currently reach around 12 per cent.

Although not as efficient as silicon cells, whose efficiencies are generally around 15 per cent, Gratzel cells are cheaper. TiO2 is a readily available material, used widely in white paint and sunscreens; organic dyes are also inexpensive. Gratzel is fond of demonstrating the system in schools, asking pupils to make their own cells using blackberry juice as the organic dye.

Within the solar cell, the dye is painted in a thin layer on a porous titanium dioxide scaffold to collect light and, in a series of steps, create power.

AN Australian company, Dyesol, supplies materials to G24 Innovations and other companies developing dye solar cell technology, said Marc Thomas, the chief executive of Dyesol’s North American operations in Sacramento. Dyesol provides the dye, titanium pastes and the electrolytes for the thin-film technology, he said. Titanium dioxide is a common, inexpensive ingredient that is used, for example, to whiten toothpaste.

Mr. Thomas noted that Dyesol customers were planning to use the technology to prolong battery life in devices like wireless sensors and keyboards.

2 Responses

I think this technology will do alot of good than harm&sceptics is the individuals that can work to the conforts of their homes amist bright lites while africa looks up to the moon to light up our village. I would like to explore probabilities about this technology. Please mail me details of how i can be involved in distributorship for the southern africa region. Thanx

Information seems a bit sketchy. Talked lots about how good it is … but at the end we find it is less efficient than what we have. It is said to be cheaper, but not how much. Efficiency varies in silicon cells, as does price. A comparison of efficiency where silicon is shown as a range instead of average and price shown as ranges would be useful. The other thing missing is durability. How long does this technology last? Can it be field refurbished (with redying)? Can it be flexible (it sounds like it might be from the uses mentioned)?