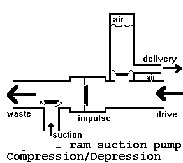

A hydraulic ram pump, sometimes called a hydram, is relatively easy to build, and can drive water up to 100 metres high. Essentially, it’s an automatic pumping device which uses a small fall of water to lift a fraction of the water available to a much greater height using only the power of gravity. Its only moving parts are two valves, and this gives it high reliability, minimal maintenance requirements and a long operational life. Its an ‘old-tech’ device that is as useful today as ever. Invented before electric water pumps, this rugged, simple and reliable device is typically installed at remote home sites for domestic water supply, watering livestock, gardens, decorative lily and fish ponds, water wheels and fountains. Because it uses no power, a ram pump can be used where water would normally not be used and would flow on downstream.

If you’re thinking of building one, check out this site for details of exactly how and why the pump works. It’s thanks to a phenomenon called ‘water hammer’, and the overall efficiency can be quite good under favourable circumstances ‘ as much as 50% of the energy of the driving flow can be transferred to the delivery flow.

One man who’s built these, Gert Breur, has developed a very easy to assemble design for a ram pump, using mainly standard garden’materials (except for some pressure tube). Even with high-quality materials the bill only comes to $50!

Your DIY shopping list:

Clamp-connection SIMPLAST WISA 25 x 3/4inch thread

T-joint brass 3/4 inch inside thread

Brass reducing coupling 1 inch to 3/4 inch outside thread

Foot valve brass 1 inch inside thread (ball shape and used in reverse direction)

O-ring nitrilrubber 6.0 mm x 1.5 mm (to regulate pump frequency)

Brass reducing coupling 1 inch to 3/4 inch outside thread

Spring-loaded check valve brass 1 inch inside thread “EUROPA”

(optional) brass quick-connect coupling “GEKA” 1 inch outside thread

(optional) Hose quick-connect brass coupling “GEKA” 1 1/4 inch

may be replaced by brass converter from 1 inch thread to 1 1/4 inch hose coupling.

Pressure tube TRICOFLEX 1 1/4 inch x 150 cm (more than 10 bar)

Hose clamp “JUBILEE” stainless steel 30-40 mm

Hose quick-connect brass coupling “GEKA” 1 1/4 inch

Hose clamp “JUBILEE” stainless steel 30-40 mm

Hose quick-connect brass coupling “GEKA” 1/2 inch

Enflontape 12 mm x 0.1 mm or fibre “WURTH” (like for central heating installations)

The material for the drive-pipe can be either a rigid (metal) pipe or, preferably, a tylene tube. The diameter must be at least as much as the ram, so around 3/4 inch. The length is expected to be several meters, from water-supply to ram.

Good luck DIY enthusiasts!

2 Responses

^

| It’s funny to me when people demand things in

| comment sections

sir,

i need a ram pump for suction the water from 50 to 60 feet depth do you have that kind of ram pump whos drive with water in depth if you have so please send me complte details

thanks.